Customer requirements

The customer has two sets of 900KW and one set of 1250KW high-voltage inverter, due to the equipment is old, the operation of the frequent failure. Inverter internal power unit failure caused by equipment downtime maintenance time increases year by year, maintenance costs remain high, and some of the internal components of the frequency converter, especially electrolytic capacitors, life is close to the limit, but the frequency converter transformers, cabinets, insulation framework, cables and other components can continue to use; the need for upgrading and transformation.

Technical programme for upgrading and reconstruction of high-voltage frequency converter

Combined with the site survey of the original inverter, we recommend the rectification plan: retain the original equipment bypass cabinet, transformer cabinet, remove the original equipment power cabinet and control cabinet, upgraded to the advanced level of Shanghai Zhongchen electronic technology production of ZCH100 series of all-digital AC high-voltage inverter drive power cabinet and control cabinet. ZCH100 series as a high-end high-voltage inverter products are suitable for the need for high dynamic performance of motor, low-speed and high-speed drive applications. Low-speed and high-speed drive applications. ZCH100 is widely used in rolling mills, conveyor belts, fans, test benches, and compressors to drive constant torque loads or square torque loads to achieve precise control and energy saving. The ZCH100 AC drive system consists of a power supply unit and a power supply unit.

The ZCH100 AC drive system consists of a power input/output unit, a matching capacitor, and an air-cooling unit. The system has a very high working capacity; the frequency conversion device has a high power factor, which improves the quality of power; the frequency conversion device has a high efficiency, small heat generation, reducing the space occupied by the equipment, effectively reducing the total amount of investment in the project, and maximising the saving of power and investment for the user;

ZCH100 has a standard HMI and logic controller, which can provide opening/closing control of high voltage circuit breakers, status monitoring; input power supply and motor operation status monitoring; as well as process monitoring from the user-defined process.

As ZCH100 itself has very strong communication function, it can use Modbus TCP/IP or profinet protocol to communicate with the master PLC, and the HMI realises the control parameter setting of the drive control system and the graphic and data display of the whole process of the system; it can also communicate with the upper control system through the area bus adapter to realise the monitoring of the whole process system. Therefore, it is also an ideal choice for high-pressure transmission products in large-scale process control systems.

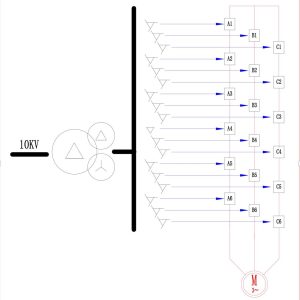

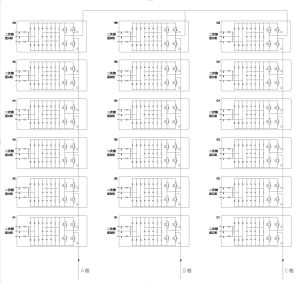

Device topology

Superior performance of the ZCH100

High torque output

The torque output of a motor driven by the ZCH100 is able to obtain the rated torque of the motor at low speeds and does not require feedback from a rotary encoder or speed measuring motor.

Flux optimisation

In optimised mode, the motor flux is automatically adapted to the load to improve efficiency while reducing motor noise. Thanks to flux optimisation, the total efficiency of the inverter and motor can be increased by 1% to 10%, depending on the load.

Speed Jump Setting

Mechanical systems may face resonance problems at certain speeds or speed bands. To avoid operating at these speeds, the ZCH100 software has up to 5 different speed settings to avoid operating at these speeds. Each speed band has an upper and lower trigger point and as the system passes through this speed band, the inverter is forced to accelerate or decelerate to the adjacent higher or lower speed to enter the allowable stable operating range, thus minimising mechanical resonance problems.

Resonance suppression

In applications where the system may be operating steadily at dangerous speeds, the usual solution is to change the mechanical design, which is time-consuming and adds to the investment cost. The ZCH100 is equipped with special torque resonance suppression software. It quickly reduces impending resonances.

Precise torque control

Dynamic torque step response time can reach 1~5ms in open-loop application, while vector control inverter needs 10~20ms in closed-loop and 100~200ms in open-loop.

Carrier frequency setting

Due to the operating characteristics of IGBT, high power transmission is not suitable for high carrier frequency operation, which will lead to a significant increase in power consumption and temperature. The carrier frequency setting is limited to 2K.

As a strength manufacturer in the inverter industry for many years, ZONCN has always been centred on the needs of the guests, to solve the pain points of the customer’s products, and is determined to provide better products and better service, no matter you need a product upgrade, or need to optimize the productivity and promote the growth of the solution, please contact us directly, and ZONCN will provide a full set of professional advice and technical solutions for the user’s reference.