Product description

Technical indicators

Input Rated voltage, frequency IPH/3PH220V50/60Hz;3PH380V50/60Hz

Voltage Allowable Range 220V:170V~240V380V:330V~440V

Output Voltage 220V:0~220V;380V:0~380V

Frequency 0.10-400.OHz

Control mode Space volume, VF control

Display Five-digit digital tube display, indicator lamp display, display set frequency, output frequency Output current, DC bus voltage, module temperature, operation status, fault, etc.

Control Characteristics

Output frequency range 0.10~400.0Hz

Frequency setting resolution Digital setting 0.01Hz Analogue setting: 0.1% of maximum output frequency

Output frequency accuracy 0.01Hz

VIF control V/F curve can be set arbitrarily to meet the needs of various loads.

Torque control Automatic boost: according to the load condition, automatically determine the torque boost, manual boost: 0.020.0% torque boost can be set.

Multi-functional input terminals 8 multi-functional input terminals for 15-segment speed control, programme operation, 4-segment acceleration/deceleration switching, UP/DOWN function, emergency stop, etc.

Multi-function output terminals 3 multi-function output terminals for indication and alarms during operation, zero speed, external abnormality, programme operation, etc.

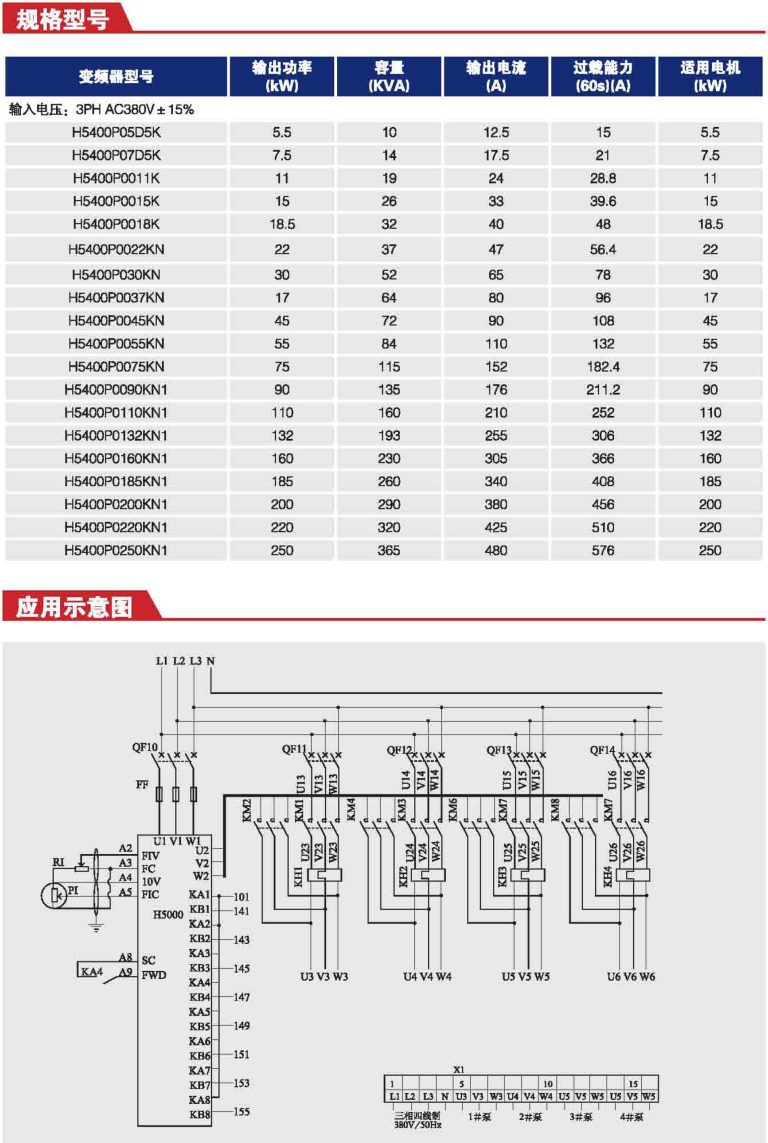

There are 8 water supply special contacts for frequency conversion, industrial frequency switching, can drag 4 sets of frequency conversion pumps.

Acceleration/deceleration time setting 06000s can be set separately for acceleration/deceleration time.

Other Functions

PID control Built-in PID control

RS485 Standard RS485 communication function (MODBUS)

Frequency setting Analogue 0~10V, 0~20mA, direct operator setting, RS485 giving UP/DOWN

Multi-segment speed 8 multi-function input terminals, can be composed of 15-segment speed

Automatic voltage stabilisation Automatic voltage stabilisation function can be selected according to needs

Counter Built-in 2 sets of counters

Kin-disk parameter shell Optionally, DP-LEDO5/DP-LEDO6 keyboard can be used to achieve this function.

Protection Function

Overload protection Constant torque 150%/1 min, variable torque 120%/1 min.

Overvoltage protection Overvoltage protection can be set

Undervoltage protection Undervoltage protection can be set

Other protections Thermal protection, short-circuit protection, over-current protection, parameter locking, etc.

Ambient Temperature -10℃ to 40℃ (no freezing)

Ambient humidity below 95% (no condensation)

Altitude 1000m or less (more than 1000m need to downgrade use)

Vibration 0.5G or less

Structure Cooling method Forced air cooling

Protection class IP20

Installation 132KW or less for wall-mounted, 160-250kW for wall-mounted or floor-standing type

FAQ

What is the Difference Between the Inverter And Variable Frequency Drive?

Inverters provide AC voltage from a DC source and can be used to power electronic and electrical equipment rated for AC supply voltage. Especially since most of our household appliances require only AC power, inverters can also be used as a source of power to run equipment during a power outage when there is a problem.

An inverter is a device used to regulate the operating speed and torque of an electric motor, which is controlled by changing the frequency and voltage of the motor’s input power supply. Inverters are widely used in industrial automation, HVAC systems, water treatment, elevators and lifting equipment, renewable energy, and transportation, etc. The main purpose of inverters is to improve system efficiency, save energy and reduce consumption, extend equipment life, and optimize control performance by regulating motor speed and torque.

Summary:

Inverters: are used to convert DC power to AC power to provide AC power suitable for household appliances or the power grid.

Inverter: Used to control the speed and torque of AC motors and realize speed control by changing the frequency and voltage of the power supply.