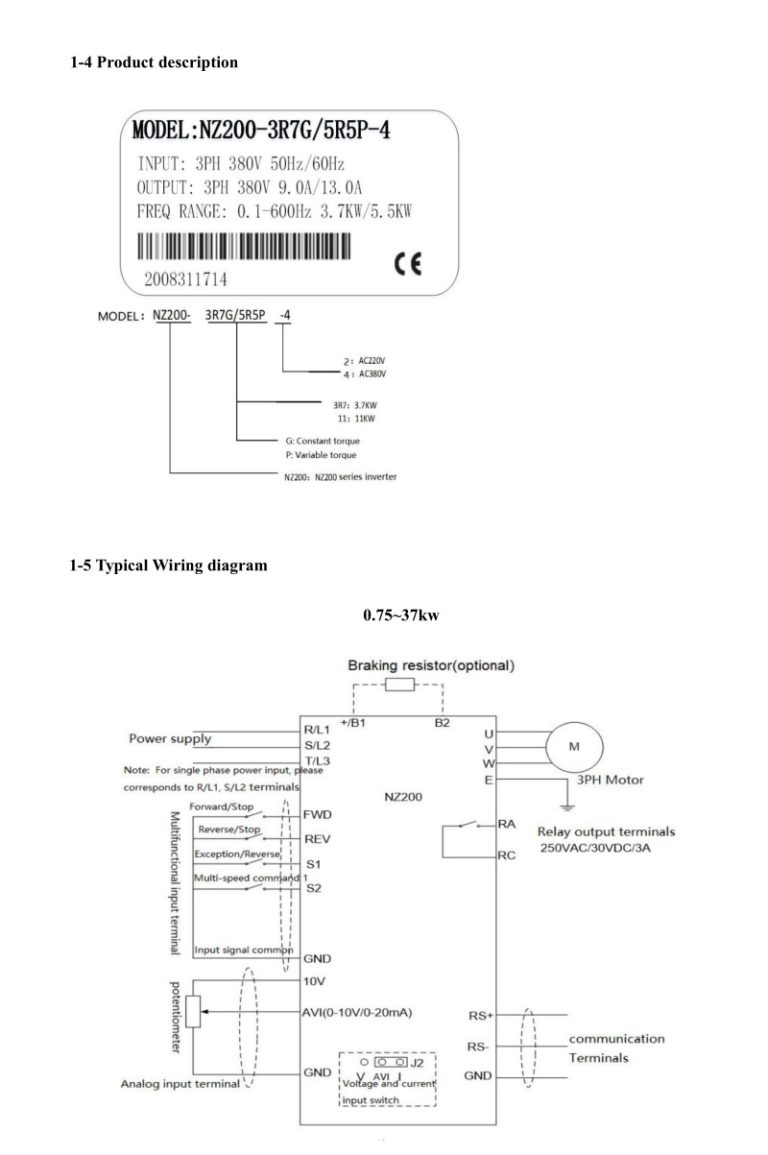

Product description

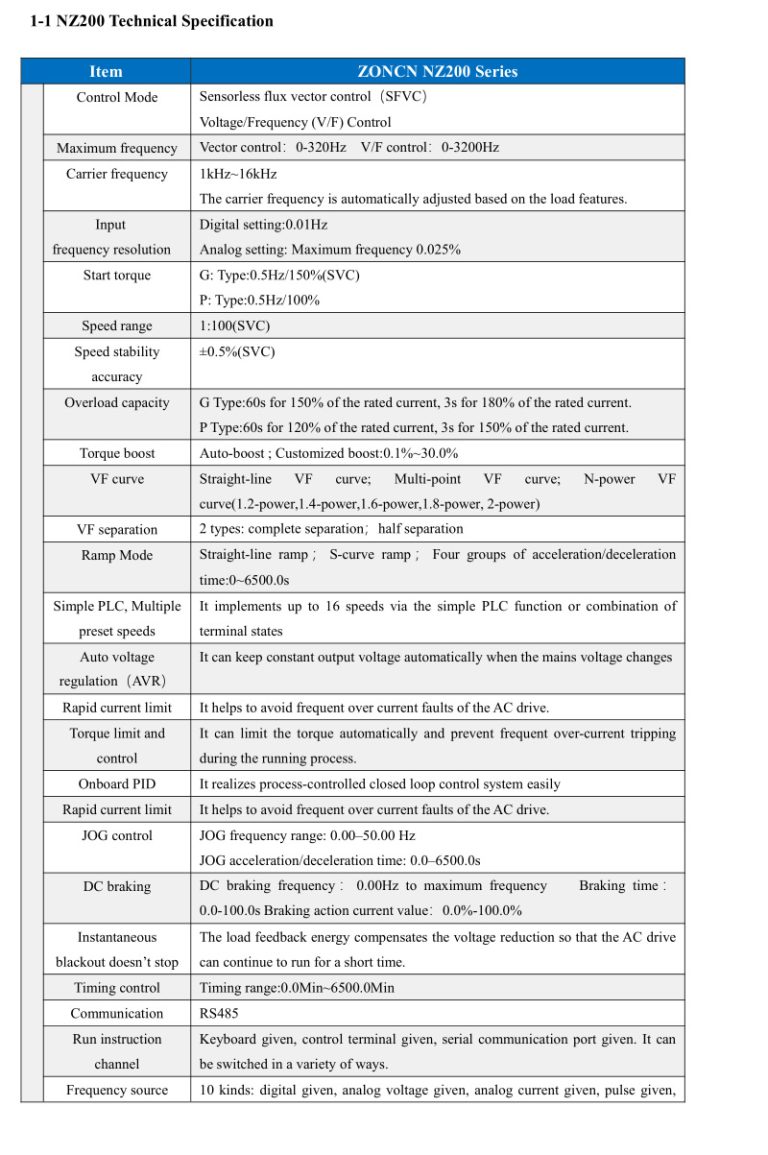

Technical specifications

Control mode V/F control Open loop volume control (no PG)

Maximum frequency Volume control: 0~320Hz VF control: 0~3200Hz

Carrier frequency 1kHz~16kHz Carrier frequency can be adjusted automatically according to the load characteristics.

Input frequency fraction Digital setting: 0.01Hz Analogue setting: Maximum frequency × 0.025%

Starting torque G-type machine: 0.5Hz/150% (without PG); P-type machine: 0.5H/100

Speed control range 1:100 (without PG)

Speed regulation accuracy ±0.5% (without PG)

Overload capacity G-type machine: 150% rated current 60s180% rated current 3s P-type machine: 120% rated current 60s150% rated current 3s

Torque increase Automatic torque increase; manual torque increase 0.1%~30.0

VIF curve Three ways: Linear; Multi-point; N-square V/F curve (1.2-square, 1.4-square, 1.6-square, 1.8-square, 2-square)

V/F separation 2 types: full separation, half separation

Acceleration and deceleration curves Linear or S-curve acceleration and deceleration methods. Four kinds of acceleration and deceleration time, acceleration and deceleration time range 0.0~6500.0s

DC braking DC braking frequency: 0.00Hz maximum frequency; braking time: 0.0s~100.0s; braking action current value: 0.0%~100.0%

Tap control Tap frequency range: 0.00Hz~50.00Hz Tap acceleration and deceleration time 0.0s~6500.0s.

Simple PLC, Multi-Segment Speed Operation Up to 16 segments speed operation by built-in PLC or control terminal.

Built-in PID Closed-loop process control system can be easily realised.

Automatic Voltage Regulation (AVR) Automatically maintains a constant output voltage when the grid voltage changes.

Over-voltage and over-voltage speed control Automatic limitation of current and voltage during operation to prevent frequent over-current and over-voltage tripping.

Fast current limiting function Minimises overcurrent faults and protects the normal operation of the inverter

Torque limiting and control “bulldozer” feature, automatic limitation of torque during operation, preventing frequent overcurrent tripping.

Individualised functions

Outstanding performance Asynchronous motor control with high-performance current loss control technology

Instantaneous stopping and non-stopping Compensate the voltage reduction by load feedback energy during instantaneous power failure, maintain the inverter to continue running for a short period of time.

Fast current limiting Avoids frequent overcurrent faults in the frequency converter.

Timing control Timing control function: Setting time range 0.0Min~6500.0Min.

Communication mode supports RS-485

Running

Run command channel Keyboard setting, control terminal setting, serial communication port setting. Can be switched in various ways

Frequency sources 10 kinds of frequency sources: digital give, analogue voltage give, analogue current give, pulse give, serial port give. Can be switched in various ways

Auxiliary frequency sources 10 types of auxiliary frequency sources. Auxiliary frequency fine-tuning and frequency synthesis can be flexibly realised.

Input terminals 6 digital input terminals, one of which supports high-speed pulse input up to 100kHz (S3 option).

2 analogue input terminals, 1 supporting only 0~10V voltage input (FIV), 1 supporting 0~10V voltage input or 4~20mA current input (FIC)

Output terminals 1 digital output terminal (MO1) 1 relay output terminal (RARBRC) 1 analogue output terminal supporting 0~20mA current output or ~10V voltage output (FOV)

Remarks X terminal is NPN type by default, if you need PNP type need to be customised.

FAQ

Can I Use An Inverter to Power My House?

Inverters have become a common device for converting direct current (DC) to alternating current (AC), bringing convenience to our lives, and many households have begun using inverters to cope with power shortages or blackouts. Home inverters can provide backup power for families and ensure the normal operation of household appliances. Especially in some remote areas, inverters can power a home without a grid connection, ensuring the continuous operation of critical equipment such as lighting, communication equipment and medical equipment, making them ideal for use as a backup power source.

Using an inverter to power a house is feasible, especially when combined with renewable energy sources such as solar or wind, to achieve a clean, independent power supply system. When selecting and installing an inverter, factors such as the home’s power requirements, battery capacity, voltage specifications, efficiency and reliability need to be taken into account to ensure that the system can operate consistently and efficiently.