Customers need new, advanced, mature, complete and safe and reliable, and the technical and economic performance of the equipment. High economic performance of the frequency control cabinet, including, but not limited to: inverter power unit cabinet; feeder and control cabinet cabinet, braking cabinet, control panel, in-disk special connection cable, ZONCN recommended custom inverter, the programme is as follows

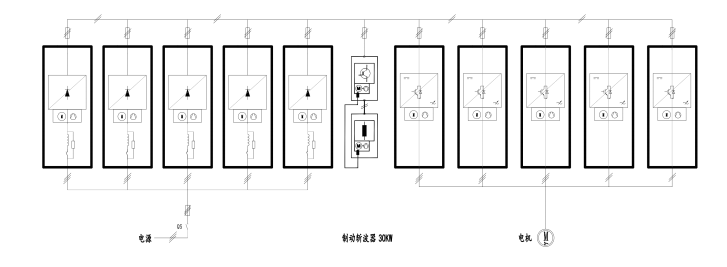

First of all, confirm the overall idea of the programme system composition: 690VAC on the user side through the load switch (circuit breaker and contactor are optional) into the pre-charging circuit, five diode rectifier units in parallel to form the power supply circuit, rectified by the five inverter units in parallel to drive the motor operation. The braking circuit is connected to the DC side, and the braking power is 30Kw.

The wiring diagram is below:

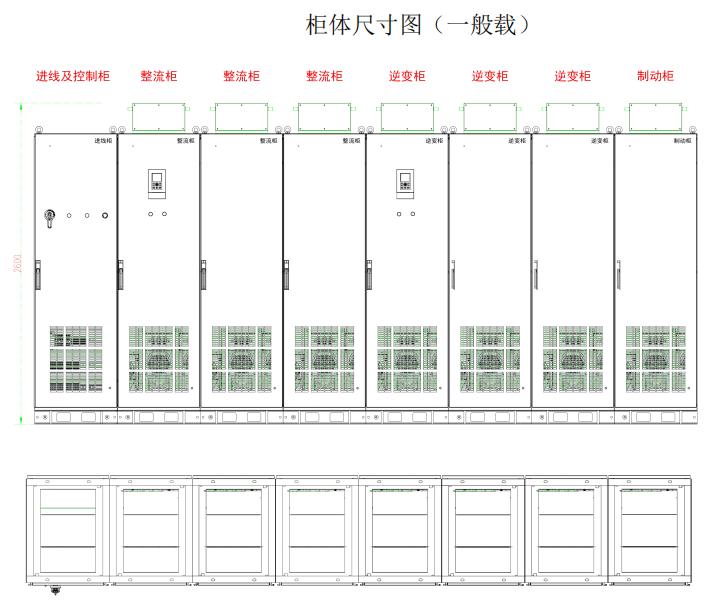

Cabinet Dimension Drawing

The inverter outputs 690V directly without any output boost.

The whole set of inverter control unit, including rectifier unit, inverter unit and auxiliary unit, all components and internal wiring are integrated.

The whole set of inverter control device, including rectifier unit, inverter unit and auxiliary unit, and all the internal wiring are integrated, so the customer only needs to connect the input, output, control power supply and monitoring data lines. The inverter has a strong adaptability to the fluctuation of the grid voltage, and can withstand an instantaneous 15% drop in the grid voltage and continue to operate at a reduced rate. The control system of the inverter adopts digital microprocessor controller, and does not use temperature-sensitive industrial control machine. The inverter control system adopts digital microprocessor controller and does not use temperature-sensitive industrial control machine. It has local monitoring mode and remote monitoring mode. The inverter is equipped with fault self-diagnosis function, which can provide Chinese instructions for the type of faults occurred, and can display locally and alarm remotely, which is convenient for operators and maintenance personnel.

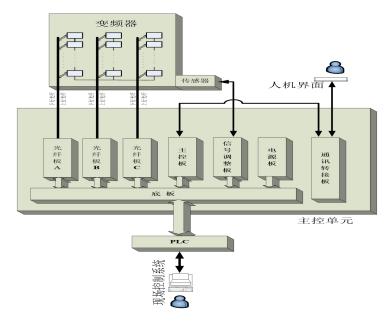

Control system of frequency converter

The internal communication of inverter adopts optical fibre cable to improve the communication rate and anti-interference ability.

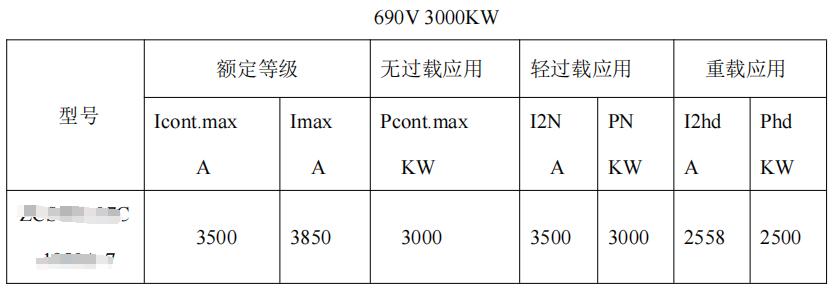

Inverter cabinet parameters:

Rated class

Icont.max Root mean square value of continuous output current. No overload capability above 40°C.

Imax Maximum output current. Allowed for 10 seconds at start-up, otherwise available as long as the drive temperature permits.

Application without overload

Pcont. max Typical motor power. This power rating can be applied to most IEC 34 motors at rated voltages of 400 V , 500 V or 690 V .

This power class can be applied to most IEC 34 motors at rated voltages of 400 V, 500 V or 690 V.

Light overload applications (110 % overload capacity)

I2N Root mean square value of the continuous output current. 10 % overload allows one minute of operation every five minutes.

PN Typical motor power. This power class can be applied to most IEC 34 motors at rated voltages of 400 V , 500 V , or 690 V .

Most IEC 34 motors at rated voltages of 400 V, 500 V or 690 V.

Heavy-duty applications (150 % overload capacity)

I2hd Root mean square value of continuous output current. 50 % overload allows one minute of operation every five minutes.

Phd Typical motor power. This power class can be applied to most IEC34 motors at rated voltages of 400 V , 500 V or 690 V. Depending on the programme requirements, the frequency converter is not only suitable for the motor power, but also for the motor power.

According to the requirements of the programme, the frequency converter can not only improve the production efficiency, but also achieve the purpose of saving energy and money, if you for the current use of inverter products, or need to keep up with the new inverter products, please contact us directly, professional frequency converter manufacturer, trustworthy.