The principle of two-stage compression screw air compressor, the compression process is natural air through the air filter into the first stage of compression, in the compression chamber with a small amount of lubricating oil mixing, at the same time compressed mixed gas to the interstage pressure. The compressed gas enters the cooling channel and comes into contact with a large amount of oil mist, thus greatly reducing the temperature. The cooled compressed gas enters the second stage rotor for second stage compression and is compressed to the final exhaust pressure.

The head of the bipolar compression screw air compressor consists of two pairs of yin and yang rotors. After the gas is compressed in the first stage, it enters the second stage of compression. The compression ratio is high and the power is one stage lower than compressed air compressor.

Technical characteristics of bipolar compression screw air compressor.

Bipolar compression screw air compressor has large exhaust volume, uniform exhaust, no pulse of airflow, easy to realize automation and large-scale. At the same time, it is characterized by fewer wearing parts, less maintenance and long operation cycle. After adding the inverter, the inverter can play a role in safety, energy saving and speed regulation.

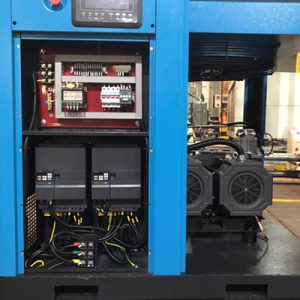

ZONCN inverter selection.

According to the actual demand of the product, the selection of inverter is generally consistent with the motor power, but the load is heavy. Here we recommend a motor specification of 380V/37KW, inverter Z2400T-18.5KY, two inverters, while the motherboard needs a small terminal port. This can better connect with the bipolar compression screw air compressor and realize the frequency adjustment function.