Product description

HMI-6070 Series Air Compressor Controller

FAQ

What Are the Controls on A Compressor?

There is a wide range of control devices on the compressor, each with a different function to ensure the safe and efficient operation of the compressor.

1. Pressure switches and sensors that monitor the system pressure, control the start and stop of the compressor when the pressure reaches a preset value, and transmit the data to the control system.

2. Temperature switches and sensors, monitor the temperature of the compressor, when the temperature exceeds the set range, send out an alarm or stop signal, and provide real-time data.

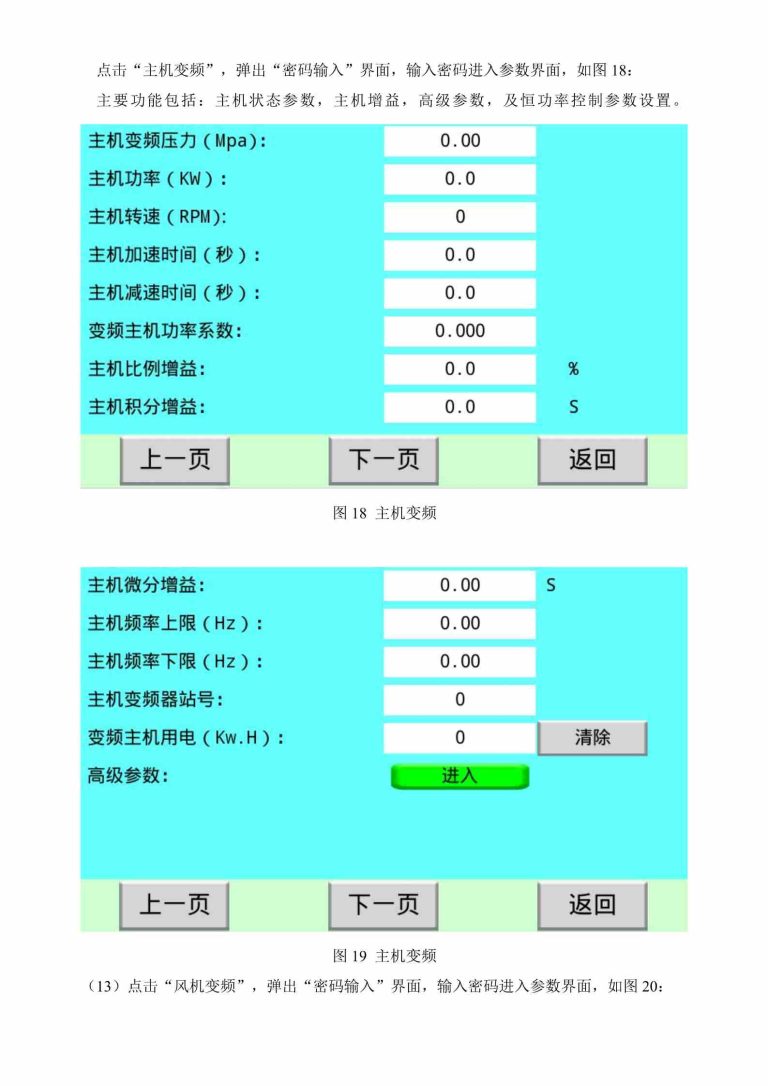

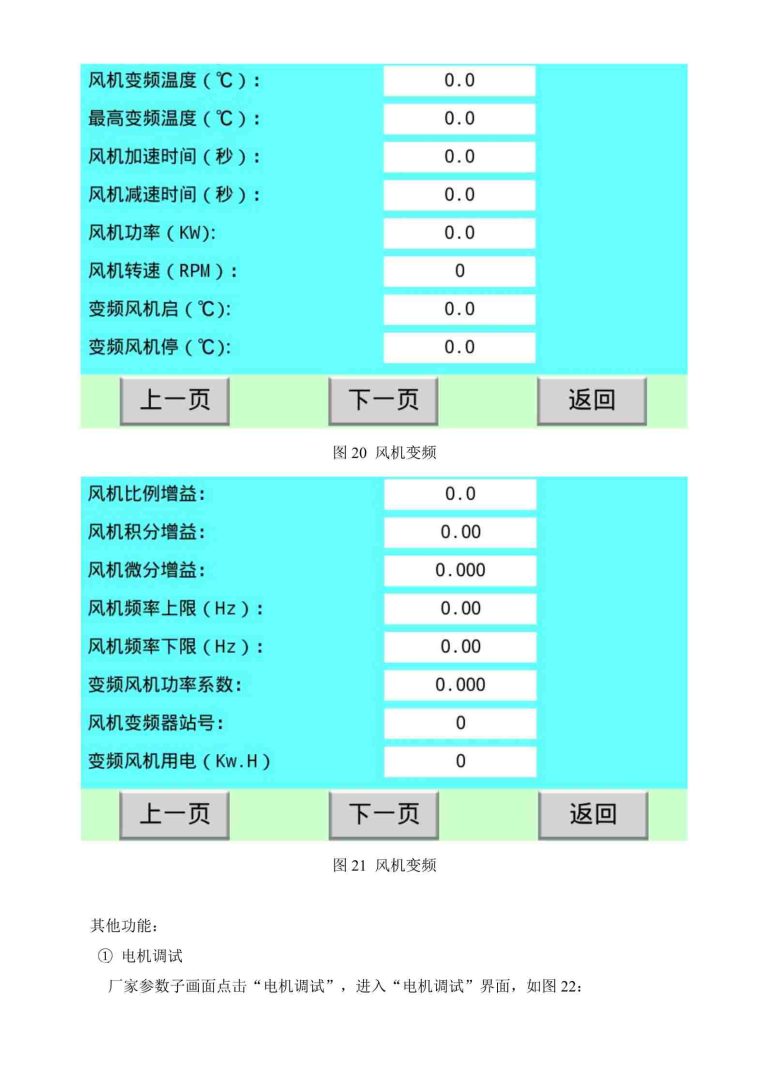

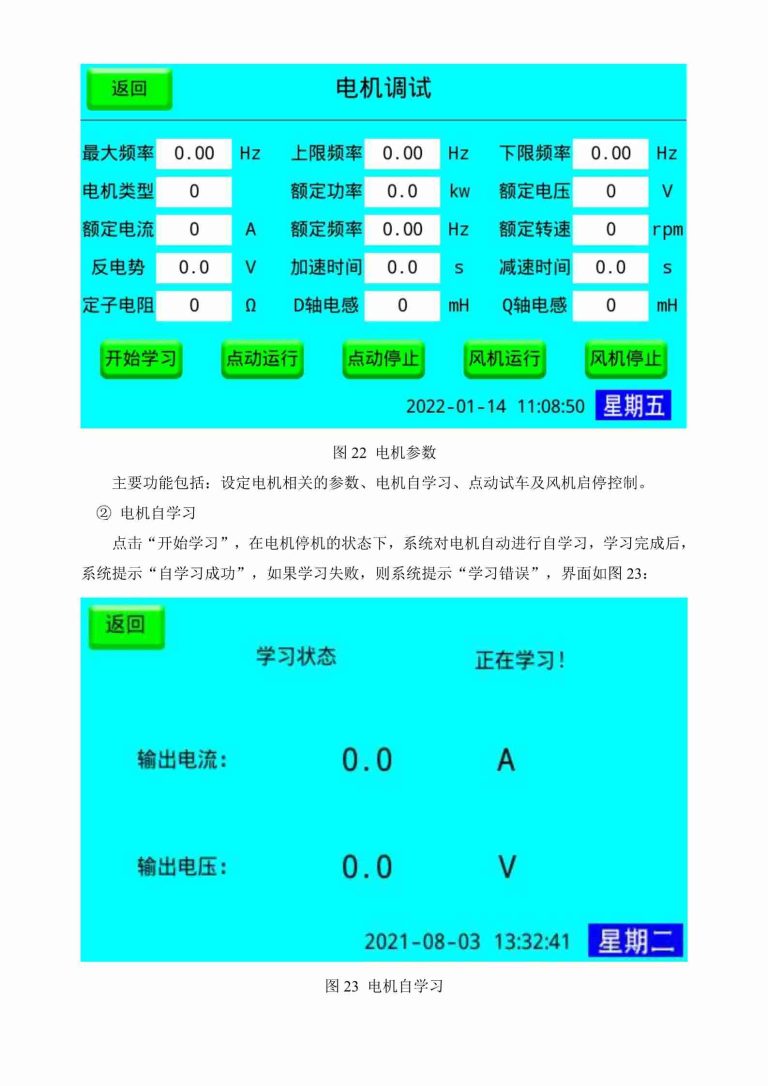

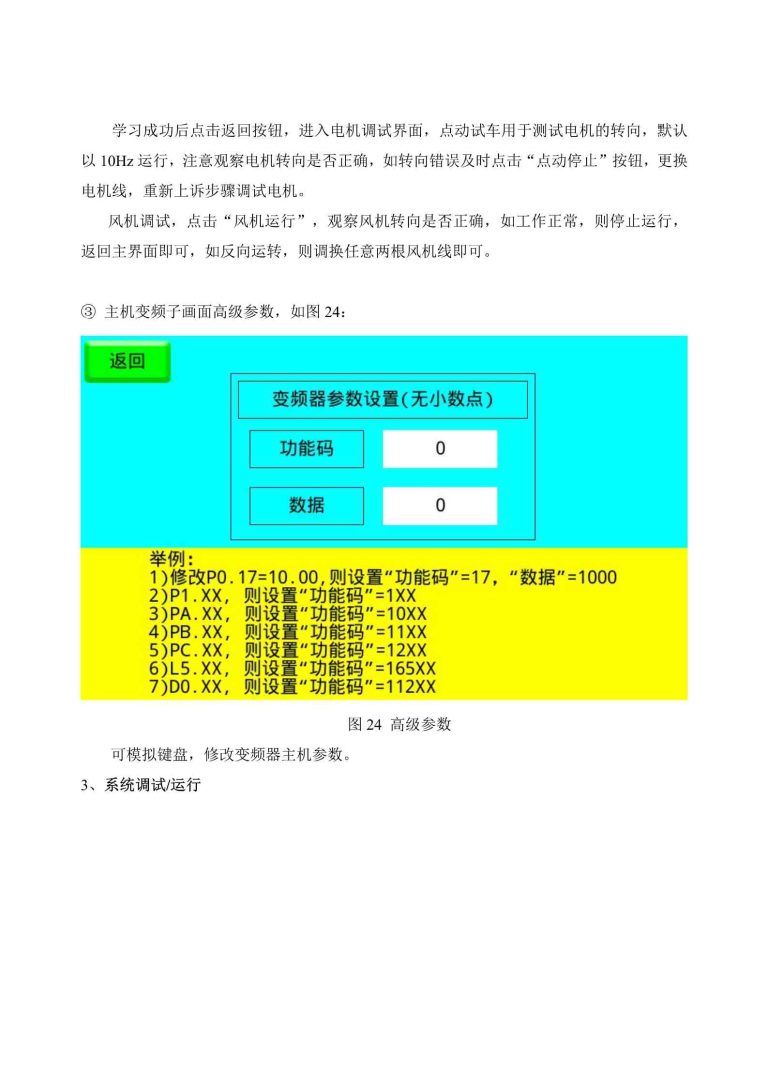

3. Frequency converter, regulates the speed of the compressor motor and adjusts the output power of the compressor according to the demand.

4. Motor starter, control the start and stop of compressor motor.

5. PLC, processing sensor signals, executing logic control, regulating the operating status of the compressor.

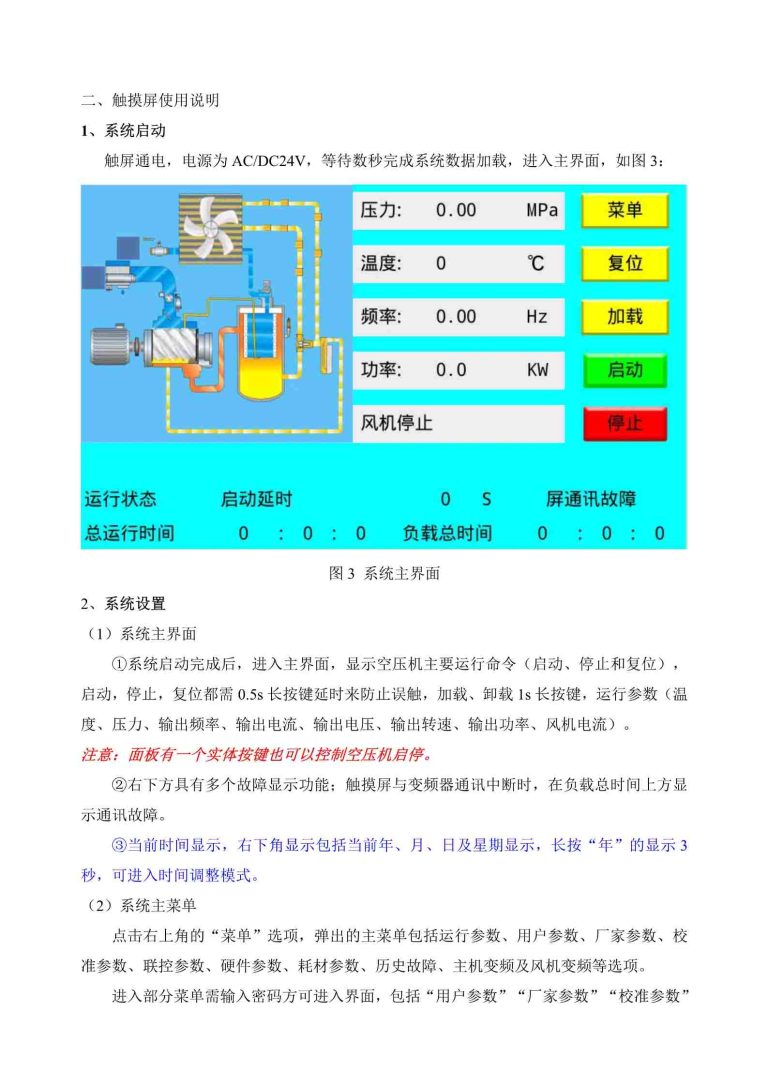

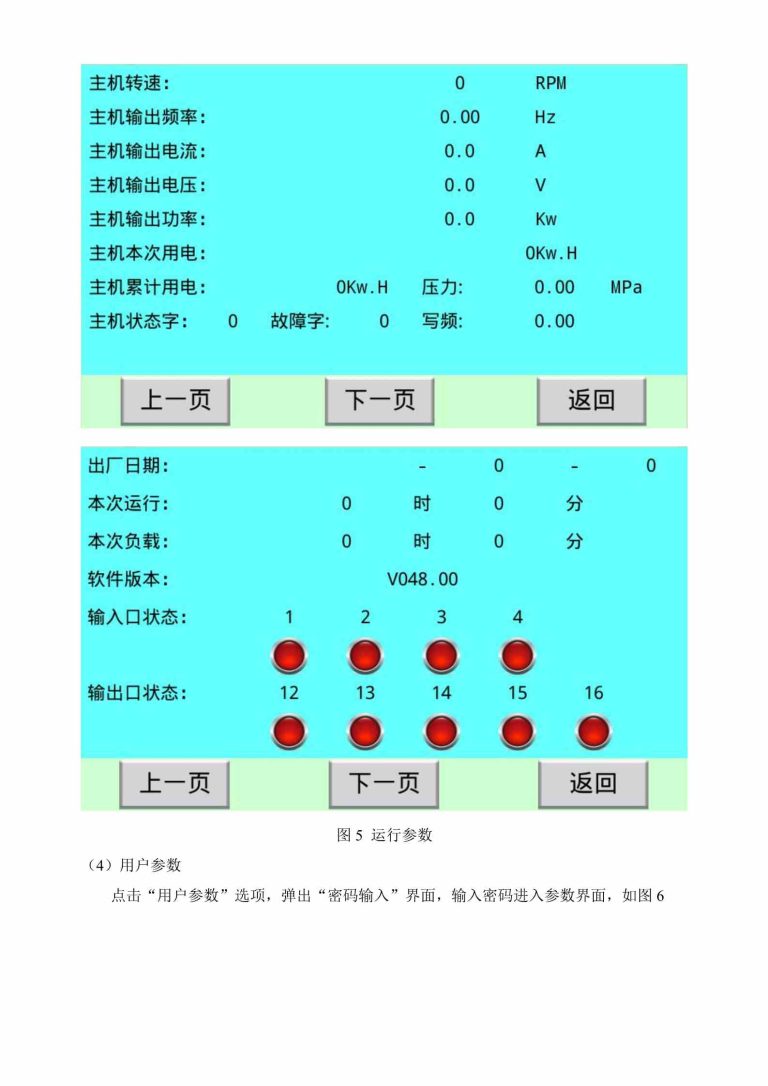

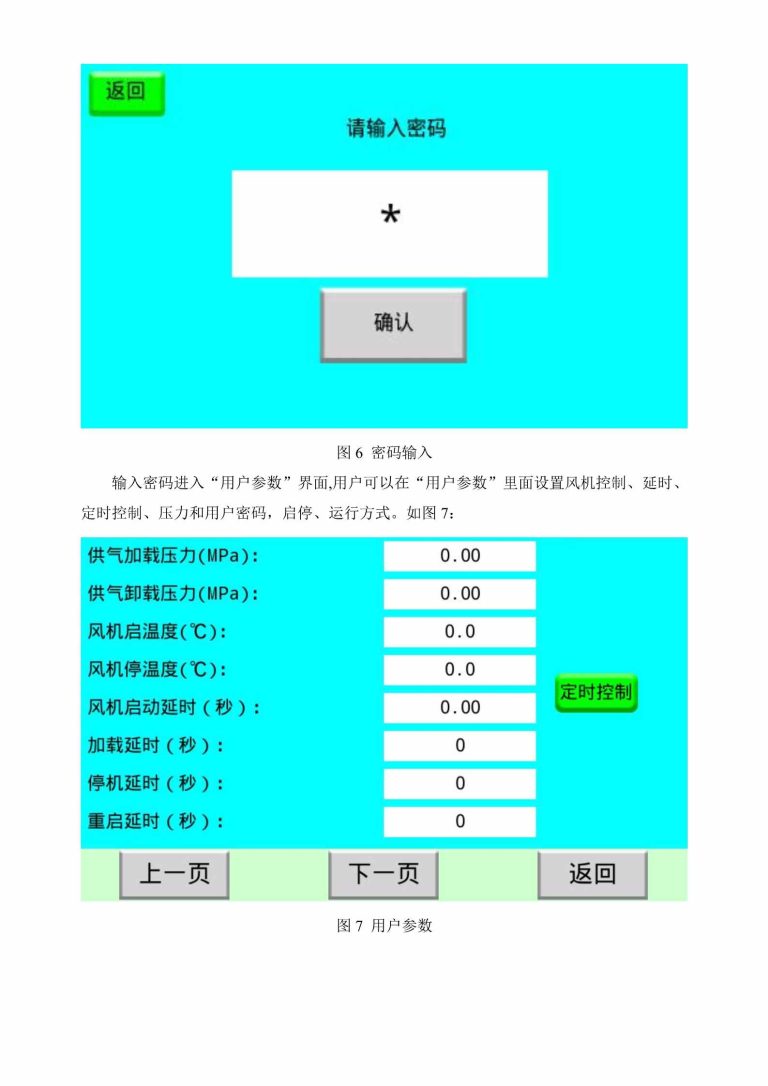

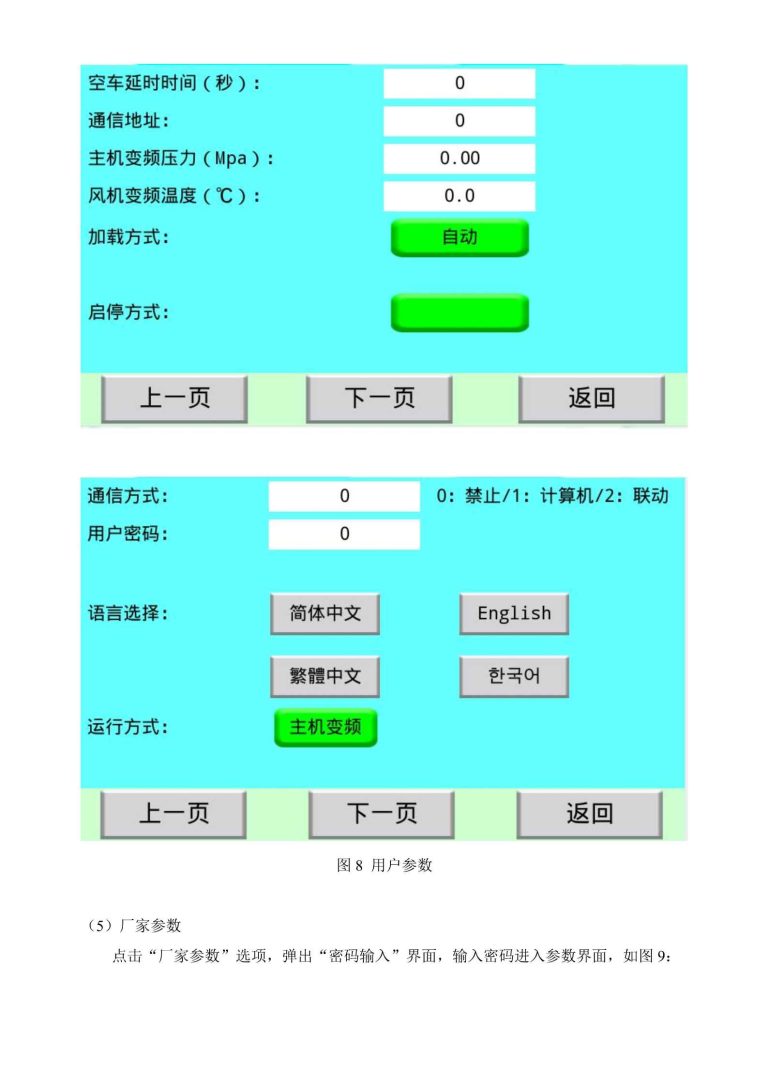

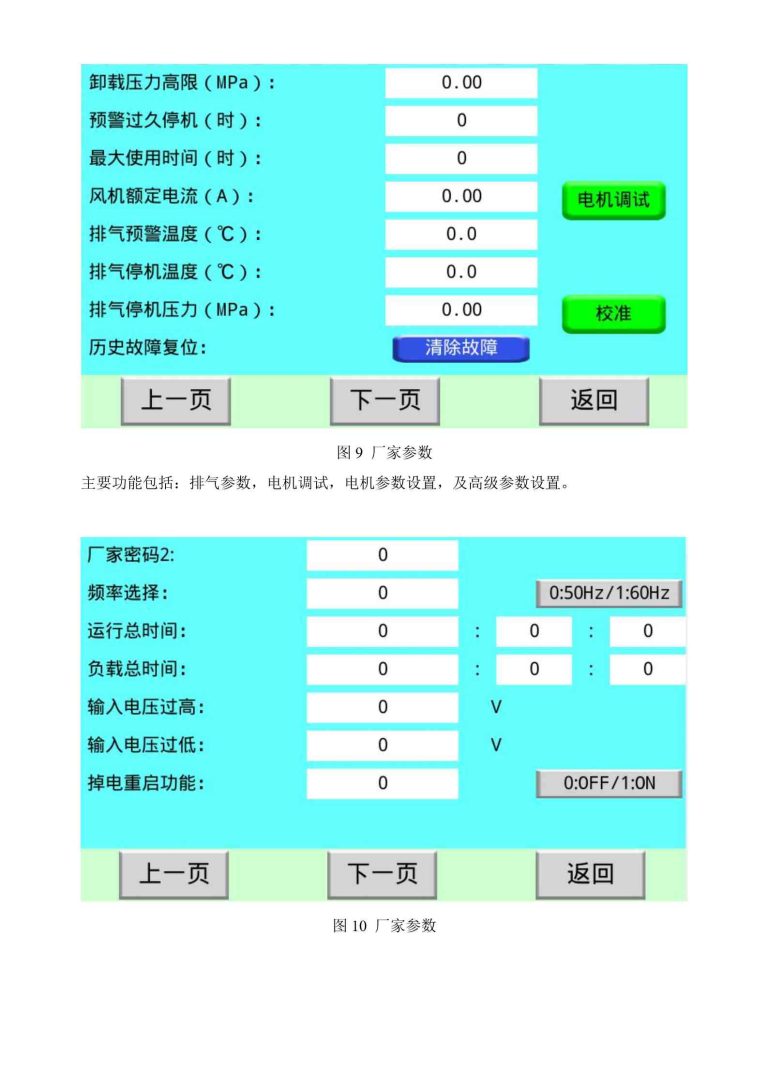

6. HMI, provides an interactive interface between the operator and the compressor control system, displaying the operating status and parameters.

7. Safety valve, in the system pressure exceeds the safety limit value automatically open, release the excessive pressure.

8. Flow control valve, regulating the compressor output gas flow.

9. Lubricating oil sensor, monitoring the pressure and temperature of the lubricating oil.

These control devices work together to ensure that the compressor in a variety of working conditions can be stable, efficient and safe operation to meet the needs of industrial production.