Product description

HMI-8080 Series Air Compressor Controller

FAQ

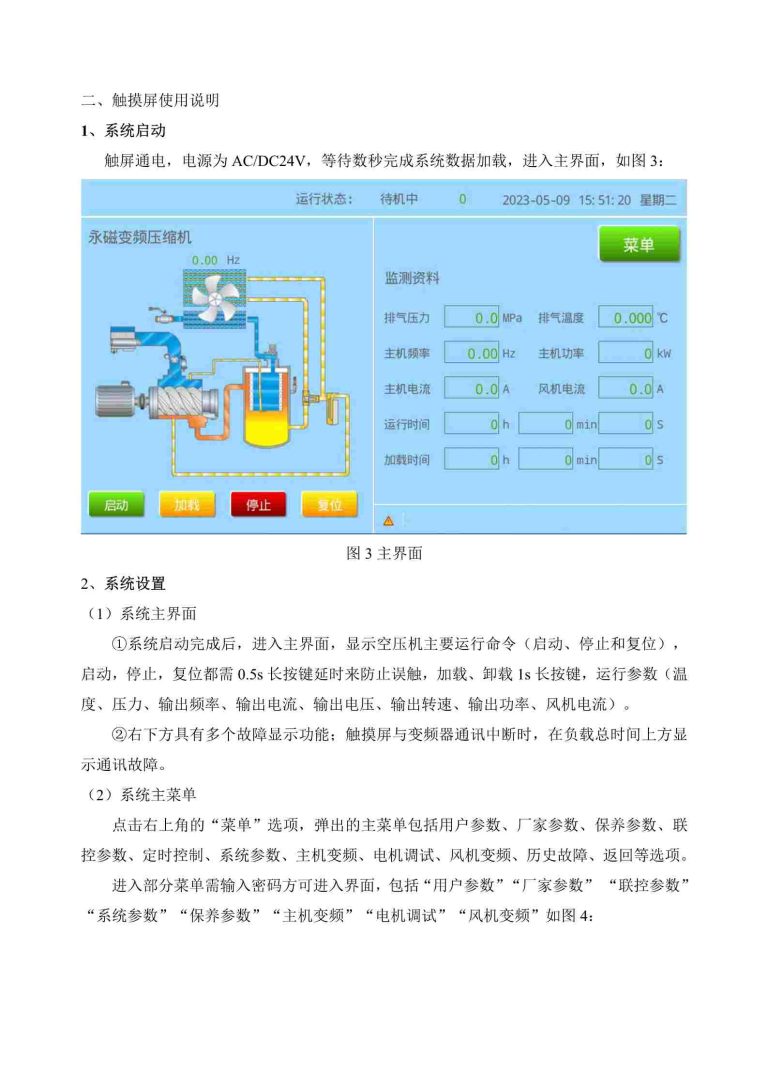

How do I control the speed of my air compressor?

Start/stop controls are usually the easiest to understand. This type of control turns the motor on or off to meet demand based on a pressure signal.

The load/unload process controls the compressor so that when the motor runs continuously and reaches sufficient discharge pressure, the compressor will unload. Once the discharge pressure is reduced to a specified insufficient level, the compressor is reloaded, allowing it to recover and perform its assigned task. This type of control is best suited for large industrial compressors and applications.

A frequency converter receives signals from the control system and adjusts the output frequency and voltage as needed to vary the speed of the motor. This type of control is considered the most efficient and saves energy. However, these controls are very sensitive to environmental factors and cannot operate at high temperatures and high heat and moisture. Overall, VFD controls are very adaptable for applications with changing demands.

The choice of speed control method depends on the specific application needs, compressor type and control requirements. Frequency converter control is one of the most common and effective methods used in modern industry for applications where energy savings and high precision control are required. For some simple applications, mechanical speed control or pneumatic control may also be suitable options.