An electric motor is a device that converts electrical energy into mechanical energy. Its working principle is based on electromagnetism, and the magnetic field generated by the current drives the rotation of the rotor, thereby achieving mechanical output.

Basic parts of electric motors

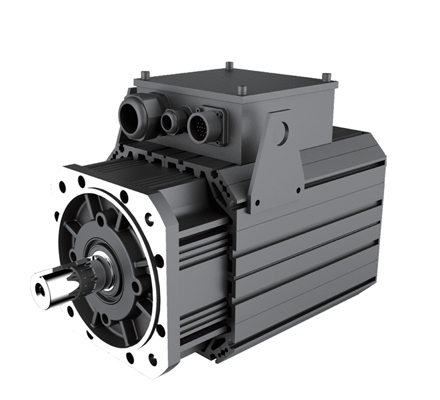

The basic parts of an electric motor are the stator and the rotor, which generate rotation and torque through the interaction of electromagnetic fields. The stator is fixed (fixed to the body of the motor), while the rotor is the part of the motor that rotates (including the shaft).

Common parts in electric motors are the central motor shaft, windings, bearings (to reduce friction and wear), armatures (located in the rotor, the rotating part, or the stator, the stationary part), brushes (in DC motors), terminals, frames, and end caps.

There are two main types of electric motors:

AC motors, which are driven by alternating current, include induction motors and synchronous motors.

DC motors, which are driven by direct current, include brushed DC motors and brushless DC motors.

DC motors operate from a power source where the current flows unidirectionally, and the current only flows in one direction. The voltage must remain constant to maintain a steady current. For example, the power generated by a battery or an AC power source, which is rectified to DC. DC motors are used in a wide range of applications, including electric wheelchairs, handheld sprayers and pumps, coffee machines, off-road equipment, etc.

An AC motor is an electric motor that is driven by an AC power source. It converts AC electrical energy into mechanical energy and outputs mechanical power by rotating. The operation of an AC motor is based on the principle of electromagnetic induction, and the rotation is achieved through the electromagnetic interaction between the rotating magnetic field generated by the stator and the rotor.

There are two types of AC motors: one is a single-phase motor and the other is a three-phase motor.

Three-phase AC motors are used in industry to convert large amounts of electricity into machinery. For small power conversion, single-phase AC motors are suitable. Single-phase AC motors are small in size and can provide different types of services in homes, offices, factories, etc. Most household appliances (such as refrigerators, fans, washing machines, hair dryers, blenders, etc.) use single-phase AC motors. AC motors are also divided into synchronous motors and induction motors.

Difference between AC and DC motors

One of the main differences between AC and DC motors is speed control. AC motors run at the frequency of the AC power supply, so the speed does not change even if the load changes. To change the speed of the motor, a variable frequency drive (VFD) must be used, which converts the AC power to DC power and then back again at a different frequency. DC motors control speed by adjusting the voltage or changing the armature current. Brushless DC motors achieve precise control through electronic controllers.

AC motors are generally more efficient and suitable for constant speed operation. However, the starting characteristics are more complicated, and induction motors usually require additional starting devices.

DC motors are simple to control, have a wide speed adjustment range, and have high starting torque.

Cost comparison of DC and AC motors

Usually, AC motors have a lower initial cost and lower maintenance costs because there are no brushes, while DC motors have a higher initial cost. In addition, due to the wide application of AC induction motors, economies of scale also make them relatively low-priced. This means that AC motors are used in most large industrial applications, while DC motors are used in small applications that require fine speed control, such as robots.

AC motors are generally considered more powerful than DC motors because they can produce higher torque using more powerful currents. AC motors are well suited for situations where motor speeds are low to medium and remain constant while motor loads vary. This is why AC motors are ubiquitous in heavy-duty, sustained-speed industrial applications.

However, DC motors are generally more efficient and make better use of their input energy. Both AC and DC motors come in a variety of sizes and strengths to meet the power needs of any industry.

Advantages of AC motors

1. AC motors are sturdy and can operate stably for a long time in various environments, and their service life is usually long.

2. AC motors can withstand large load changes, especially in industrial applications.

3. AC motors can easily achieve speed regulation and torque control through variable frequency drives (VFDs).

4. Most AC motors run smoothly and produce less noise and vibration, which is conducive to environmental protection and improvement of the operating environment.

5. AC motors can effectively transfer energy and are more suitable for high-power or high-speed applications (washing machines, refrigerators, machinery).

Advantages of DC motors

DC motors are generally more efficient and can effectively convert electrical energy into mechanical energy

DC motors can output higher torque at low speeds and are suitable for applications under high load conditions

DC motors respond quickly to changes in input signals and are suitable for applications that require fast response, such as robots and drones.

Although brushed DC motors require regular replacement of brushes, overall maintenance is simple. Brushless DC motors (BLDC) require less maintenance.

DC motors can be designed to be waterproof, dustproof and explosion-proof, suitable for various special environments.

Through these differences, we can see that AC motors and DC motors have their own advantages and disadvantages and are suitable for different applications. The choice of motor should be determined based on specific usage requirements, control requirements, maintenance conditions and other factors. At the same time, we also recommend that you seek help from professionals. ZONCN has been focusing on the research and development and production of inverters. We have a whole team to provide you with the best guarantee. Welcome to contact ZONCN team.