Product description

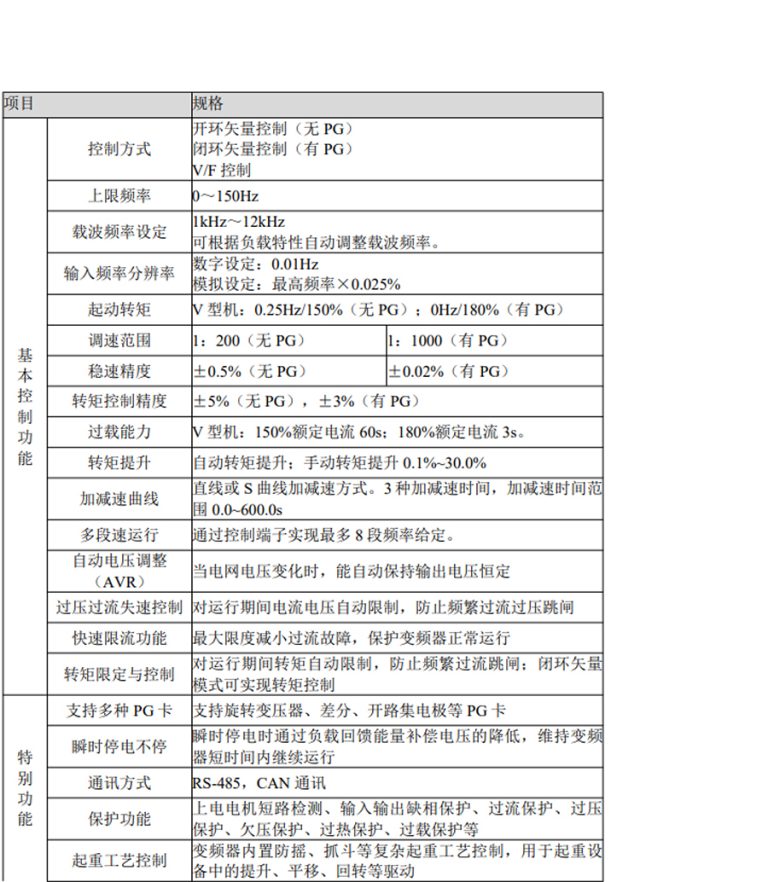

Basic Control Functions

Control method Open loop volume control (without PG) Loop volume control (with PG) V/F control

Upper limit frequency 150Hz

Carrier frequency setting 1kHz~12kHz Carrier frequency can be adjusted automatically according to load characteristics

Input frequency resolution Digital setting: 0.01HZ Analogue setting: Maximum frequency × 0.025%

Starting torque Model: 0.25Hz/150% (without PG): 0Hz/180% (with PG)

Speed control range 1: 200 (without PG) 1: 1000 (with PG)

Speed regulation accuracy ±0.5% (without PG) ±0.02% (with PG)

Overload capacity Model: 150% of rated current 60s 180% of rated current 3s

Torque Increase Automatic torque increase: manual torque increase 0.1%~30.0%

Acceleration and deceleration curves Linear or S-curve acceleration and deceleration modes. 3 types of acceleration and deceleration times, acceleration and deceleration times range from 0.0 to 600.0s.

Multi-band speed operation Up to 8-band frequency setting through the control terminal.

AVR (Automatic Voltage Regulation) The output voltage can be automatically kept constant when the grid voltage changes.

Over-voltage and over-voltage speed control White-action limitation of current and voltage during operation prevents frequent over-current and over-voltage tripping.

Fast current limiting function minimises overcurrent faults and protects the normal operation of the frequency converter.

Torque limitation and control Automatic limitation of torque during operation to prevent frequent overcurrent tripping: closed-loop quantitative torque control can be realised.

Special Features

Supports various PG cards Supports PG cards such as resolver, differential, open collector, etc.

Instantaneous power failure without stopping When the power failure through the load back to compensate for the reduction in voltage, to maintain the frequency conversion, electrical appliances continue to run for a short time.

Communication mode RS-485, CAN communication

Protection function Motor short circuit detection, input and output phase loss protection, over-current protection, over-voltage protection, under-voltage protection, overheating protection, overload protection, etc.

Lifting process control Inverter built-in anti-shaking, grab and other complex lifting process control, for lifting equipment in the lifting, panning, slewing and other drive

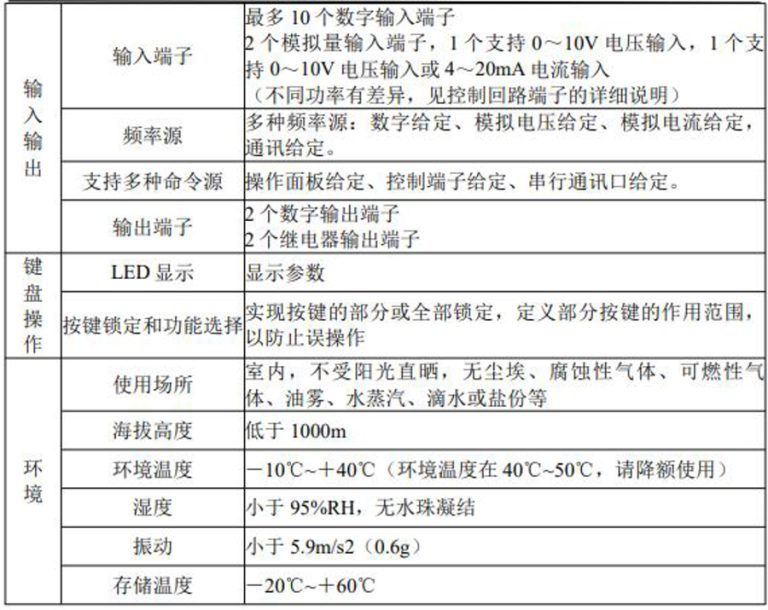

Inputs and outputs

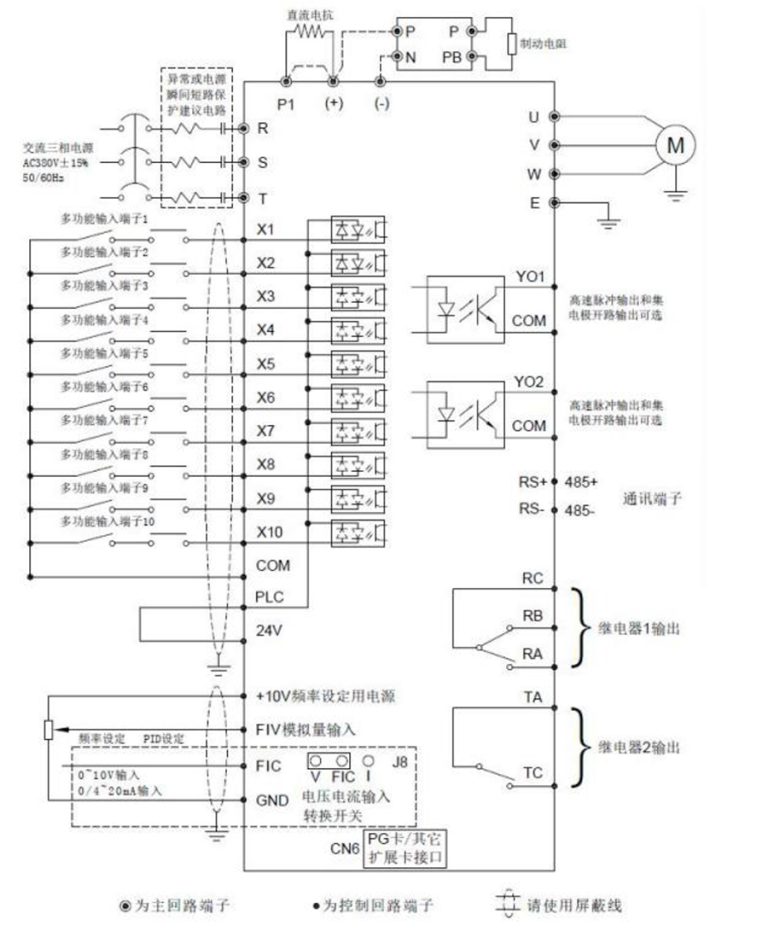

Input terminals Up to 10 digital input terminals 2 analogue input terminals, 1 supports 010V voltage input, 1 supports 0~10V voltage input or 4~20mA current input (different power variations, see the detailed description of the control circuit terminals)

Frequency source Multiple frequency sources: digital give and take, analogue voltage give and take, analogue current give and take Communication give and take.

Supports various command sources Operator panel setting, control terminal setting, serial communication port setting.

Output terminals Digital output terminals Relay output terminals

Keyboard operation

LED display Parameter display

Key locking and function selection Partial or full locking of keys, definition of the range of action of some keys Key locking and function selection to prevent misoperation

Environment

Indoors, out of direct sunlight, free from dust, corrosive gases, flammable gases, oil mist, water vapour, dripping water or salt.

Altitude Less than 1000m

Ambient temperature 10℃~+40℃ (Please reduce the amount of use if the ambient temperature is 40℃~50℃)

Humidity Less than 95%RH, no water droplets condensation

Vibration Less than 5.9m/s2 (0.6g)

Storage Temperature 20℃~+60℃

FAQ

How Many Types of Frequency Converters Are There?

Inverters can be divided into low-voltage inverters and high-voltage inverters according to input voltage levels. Common low-voltage inverters in China include single-phase inverters and three-phase inverters. High-voltage frequency converters commonly include 6kV and 10kV transformers, and the control method is generally converted according to high-low-high-frequency conversion or high-high-frequency conversion.

Low voltage frequency converter

Suitable for low-voltage motors, usually operating voltage below 690V.

Widely used in industrial and commercial fields.

High voltage frequency converter

Suitable for high-voltage motors, the working voltage is usually above 690V, even reaching several thousand volts.

Used in large industrial equipment and power transmission systems.